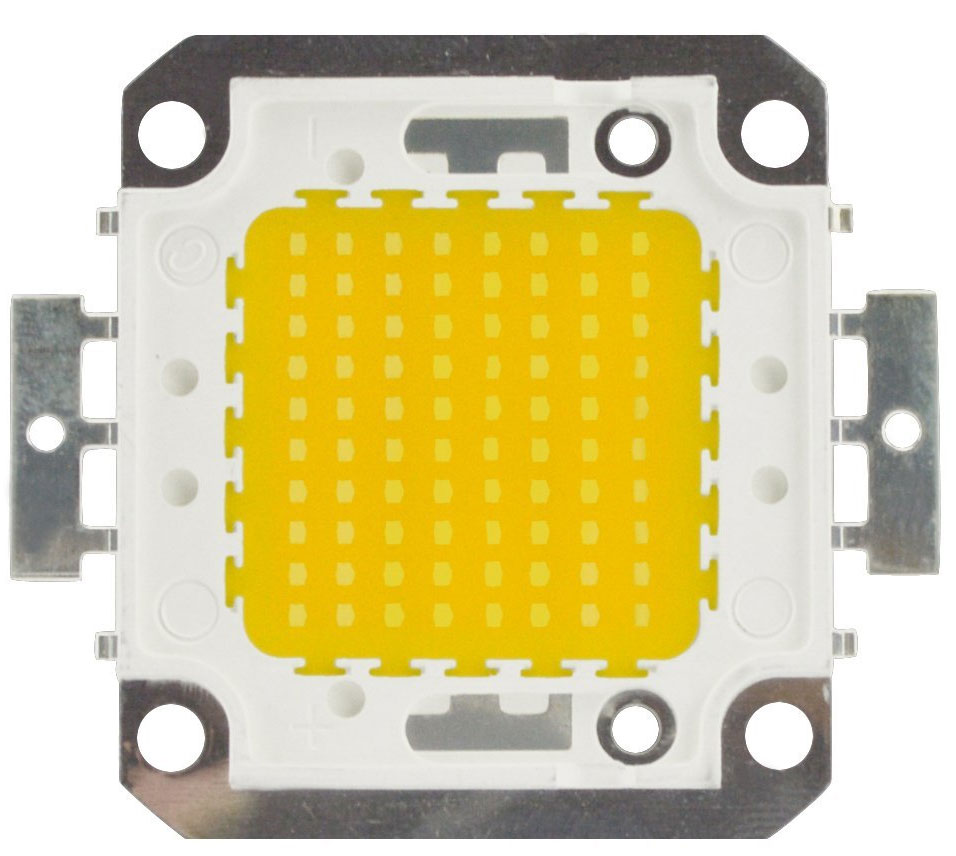

When I realized how inexpensive powerful LED chips became I decided to look into building my own Super Duper LED Flashlight. But before I can do that, I wanted to see what it takes to drive a 100 Watt LED array. So I got this LOHAS 100W LED Chip off Amazon for around $10, and a DROK... Continue reading

Subscribe

Menu

Categories

Wishlist

Please, enable Wishlist.

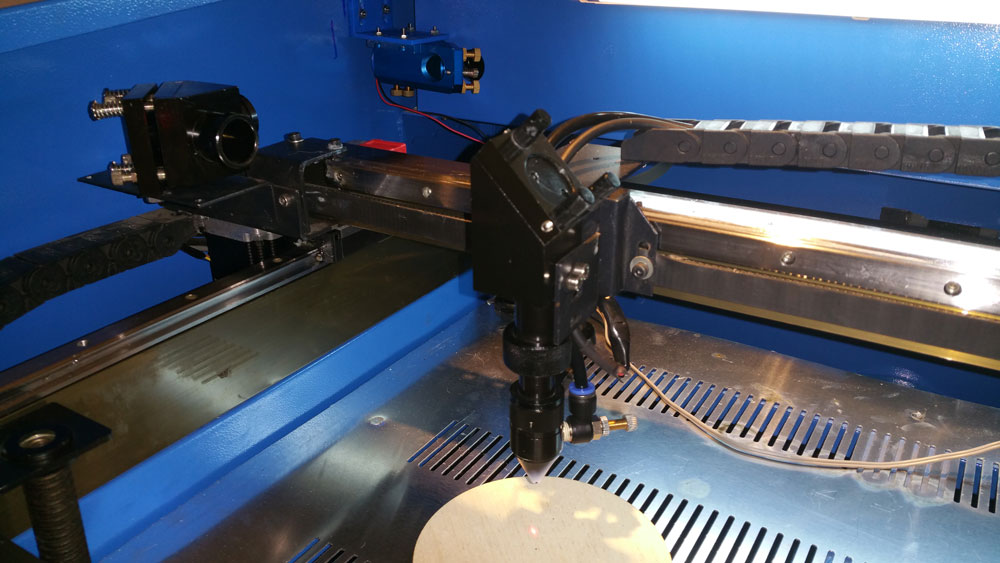

It’s been almost a month since i upgraded my SH-G350 laser cutter to 60Watts of cutting power. Here’s at last a comprehensive How To guide for all you DIYers out there. Continue reading

13

Jan

DIY pin table that I made a while back seemed great at first, but then I realized that not all rivets have same height. I only measured few from first box, and they looked to be same height, so I didn’t check others. I didn’t really notice this until recently and got a bit upset. So meet DIY... Continue reading

18

Dec

Ammeter add-on was on my to do list for a long time. It’s important to know what current is flowing thru your CO2 tube so you don’t shorten it’s life. Ammeter measures current and in case of this SH-G350 machine you’ll want ammeter rated in the 0-30 or 0-50mA range because most CO2 laser tubes run under currents... Continue reading

20

Nov

For this year I decided to do a Circus themed Halloween party. One of the major props for the part was supposed to be a large lighted “Circus” marquee sign (also called dimensional lettering). There are more than few tutorials on how to make such sign, most of them involve using some kind of thin sheet... Continue reading

05

Nov

Today I feel like I won the lottery. My first prototype of the 32×16 LED board is fully assembled and working! Continue reading

12

Aug

This is just a quick preview on what’s “cooking” at LensDigital lab. About a 2-3 weeks ago I started working on new Xronos Clock (ver 3.0). Xronos 2.0 has been out more than two years, and for a long time I’ve wanted to update this platform. Things like better Real Time chip, smaller enclosure, less expensive... Continue reading

24

Jul

CO2 Laser cutters are insanely cool, but there’s one problem. We cannot see infrared beam, so it’s always a guesswork where laser is actually will hit the work piece. Many laser cutters including SH-G350 come with a red laser pointer attached near head cone, but they are far from accurate. One that came with my machine... Continue reading

10

Jul

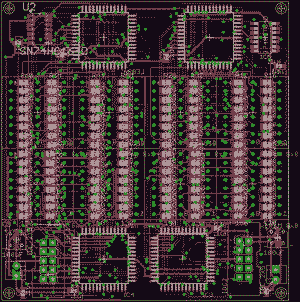

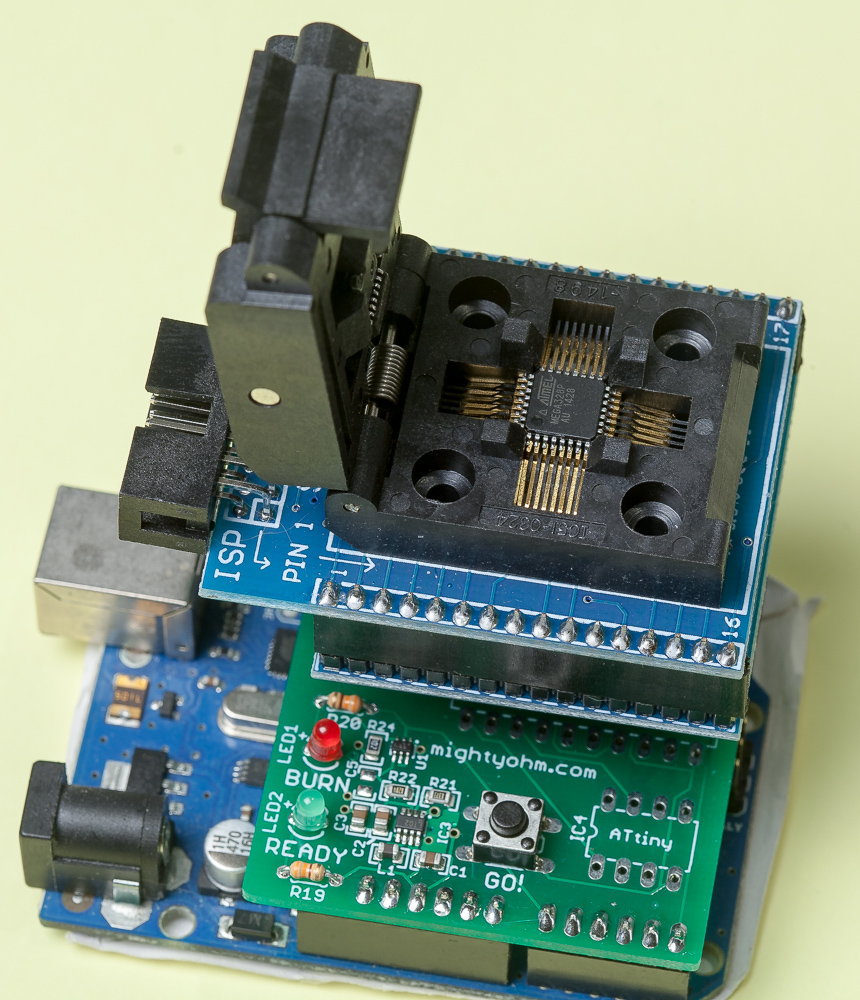

brick verb cause (a smartphone or other electronic device) to become completely unable to function, typically on a permanent basis. “installing an unofficial OS voids the warranty and may brick the phone” Lately I’ve been working on a custom “arduino clone” board that uses SMD version of ATMega328p microprocessor. This is what it looks like, magnified.... Continue reading

30

Jun

Recently I upgraded my Ryobi 10″ compound miter saw to a Dewalt DW17 (Type 3) 12″ saw. As I don’t have dust management system in my garage, I always hooked up my Craftsman 6HP shop vac directly to saw’s exhaust. Shop Vac’s hose is 2″ ID so it fit nicely my Ryobi miter saw (it would... Continue reading

30

Jun

Showing 11–20 of 28 posts